Feasibility plan

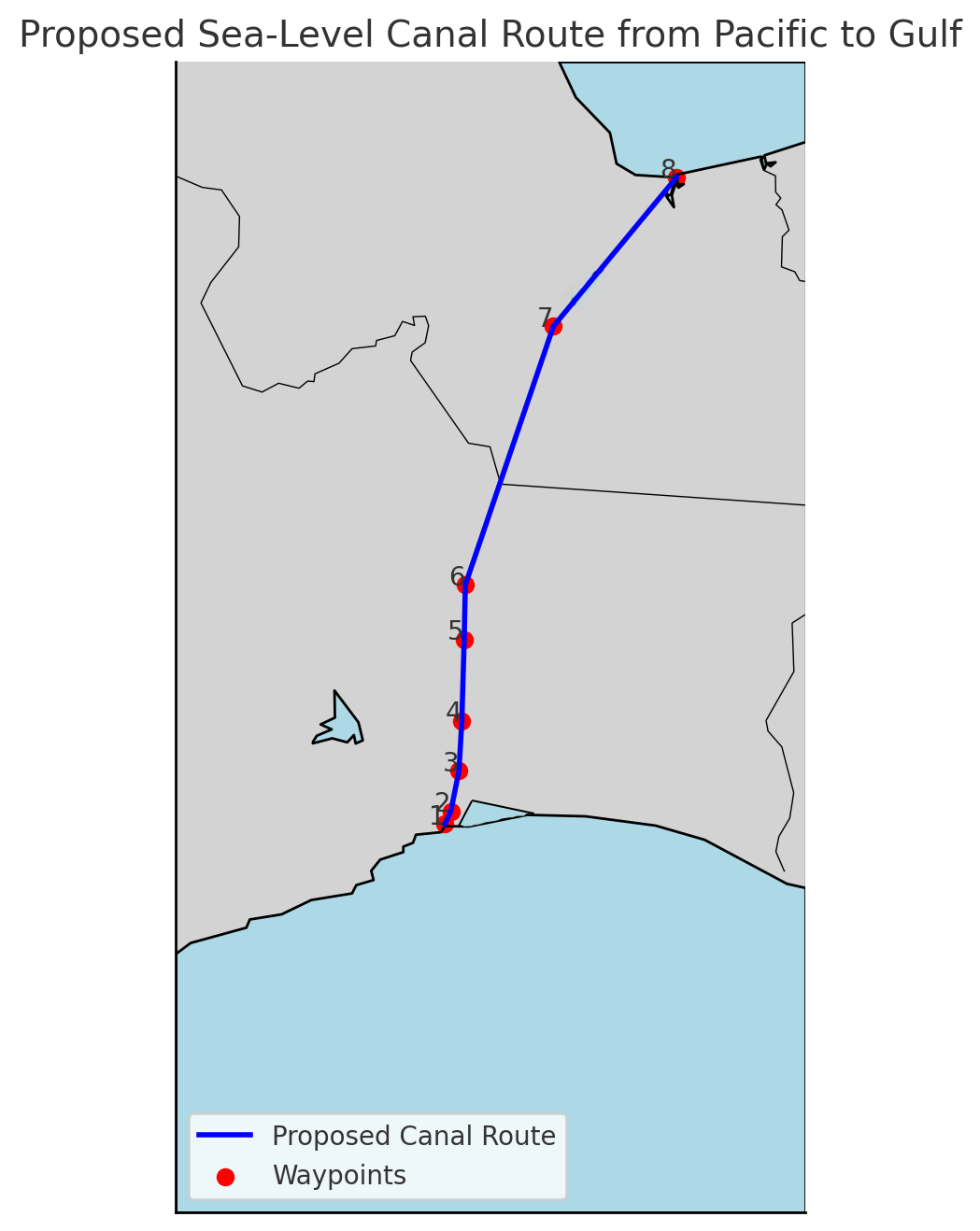

For a sea-level canal following the newly specified coordinates from the Pacific side (near Salina Cruz, Oaxaca) to the Gulf side (near Coatzacoalcos, Veracruz). The route spans eight key coordinate points (Start + 6 waypoints + End). This plan assumes:

A sea-level canal (no locks), about 600 feet wide and ~50–60 feet deep.

Primary excavation by Bucket-Wheel Excavators (BWEs), supplemented where necessary by drilling/blasting or dredges.

A target completion of roughly 10 years from project inception to operational status.

1. ROUTE AND COORDINATES

Start (Pacific Side)

16°11'21"N, 95°08'39"W

Near Salina Cruz, low coastal plains.

Waypoint 1

16°13'37"N, 95°07'32"W

Waypoint 2

16°21'02"N, 95°05'59"W

Waypoint 3

16°30'10"N, 95°05'26"W

Waypoint 4

16°45'02"N, 95°04'59"W

Waypoint 5

16°55'00"N, 95°04'44"W

Waypoint 6

17°42'03"N, 94°47'59"W

A larger jump north, indicating probable crossing of the Isthmus interior.

End (Gulf Side)

18°09'01"N, 94°24'33"W

Near Coatzacoalcos, Veracruz (Atlantic/Caribbean/Gulf side).

1.1 Approximate Distance

Based on straight-line segments connecting these points, the route likely spans around 180–200 km (110–125 mi). Final distance depends on minor adjustments to avoid localized ridges or rock outcrops.

1.2 General Terrain Overview

Start to Waypoint 5 (16°55'N): Primarily gentle coastal plains and rolling terrain with some low foothills in the interior. Elevations mostly under ~200–300 meters, with potential for small ridges around Chivela-like areas.

Waypoint 5 to Waypoint 6 (17°42'N): This segment likely encounters the central ridge portion of the Isthmus, where elevation can approach 200–250 meters.

Waypoint 6 to End: Descending toward the Gulf of Mexico coastal plains near Coatzacoalcos, typically lower, flatter floodplains.

2. TOPOGRAPHIC & GEOTECHNICAL ASSESSMENT

Lowland/Coastal Sections

Soil Type: Clays, silts, sands, possibly marshy in places. Ideal for BWEs if stabilized with geotextile causeways.

Elevation: 0–100 m (roughly), gentle slope.

Central Foothills/Ridge (particularly around ~17°–17.5°N)

Soil/Rock Mix: Potential for volcanic or metamorphic outcrops. In harder zones, drilling/blasting may be required before BWEs can remove loosened material.

Elevation: 100–250 m in some ridges.

Northern Descent (Waypoint 6 → Gulf)

Returning to lower, flatter terrain as we approach the Coatzacoalcos River basin.

Soft alluvial soils, prone to flooding—BWEs can be highly productive if causeways are carefully built.

Next Step: High-resolution LIDAR and on-the-ground geotechnical borings are essential to refine exactly where blasting is needed versus purely BWE excavation.

3. EXCAVATION STRATEGY & SECTION BREAKDOWN

For simplicity, we divide the route into three major sections based on terrain type:

3.1 Section A: Pacific Lowlands

Coordinates Range: Start (16°11'N) → ~16°55'N (Waypoint 5)

Length: ~70–80 km

Terrain: Predominantly soft coastal plains, mild foothills.

Method:

BWEs for bulk removal, with minimal drilling.

Causeways & Geotextiles to support heavy equipment where soil is waterlogged.

3.2 Section B: Central Ridge

Coordinates Range: ~16°55'N → ~17°42'N (Waypoint 6)

Length: ~80 km

Terrain: Rises to 200–250 m, possible rock outcrops.

Method:

Hybrid approach: drilling & blasting in the hardest rock zones, followed by BWEs removing fractured materials.

Heaviest earthmoving challenge, largest volume of spoil.

3.3 Section C: Gulf Lowlands

Coordinates Range: ~17°42'N → 18°09'N (End)

Length: ~40–50 km

Terrain: Downsloping plains and wetlands near Coatzacoalcos.

Method:

BWEs with strong causeway strategies.

Final dredging near the Gulf side to ensure navigable depth for large vessels.

4. INFRASTRUCTURE & EQUIPMENT

4.1 Bucket-Wheel Excavators (BWEs)

Quantity: ~15–20 large BWEs to meet a <10-year goal.

Production Rate: ~150,000 m³/day per BWE in soft soils (optimistic). Less in rocky areas.

Manufacturers: ThyssenKrupp, TAKRAF. Potential U.S. assembly lines (e.g., fast-tracked near major steel or heavy industrial plants).

4.2 Supporting Equipment

Drilling & Blasting Units

For ridge sections. Teams of 50–100 people per segment with multiple drilling rigs, explosive supply.

Dozers, Graders, Loaders

Prepare causeways, maintain haul roads, shape side slopes.

Conveyor Belts & Spreaders

Efficient spoil transport away from BWE faces to disposal or reclamation sites.

Dredgers (Cutter Suction, Hopper)

Final shaping near the Gulf/pacific entry points.

Amphibious Excavators

Handle extremely marshy terrain in low-lying segments.

5. SPOIL MANAGEMENT

Assuming 5–7+ billion cubic meters of total excavation:

Land Reclamation

Create or expand coastal land near Salina Cruz (Pacific) and Coatzacoalcos (Gulf side) for ports, industrial/logistics zones.

Causeway & Embankments

Use spoil to build elevated corridors (rail, roads) or flood protection berms along the canal path.

Commercial Aggregate

If any fraction of the rock is suitable, it can be sold or used in regional construction projects.

Designated Spoil Banks

Engineer stable “spoil banks” at safe distances from the canal edges, preventing re-slumping.

6. TIMELINE & PHASING

Total Target: ~10 years (start to operational).

Years 0–1: Preparatory Phase

Final alignment surveys (LIDAR, geotech borings).

Environmental & Social Impact Assessments (fast-tracked).

BWE design contracts & new U.S. assembly line setup.

Begin site mobilization, causeway test sections, blasting test in ridge areas.

Years 2–3: Initial Excavation & Ramp-Up

Arrival of first 4–6 BWEs.

Start heavy blasting in toughest zones, partial excavation in easier lowland stretches.

Years 4–7: Peak Parallel Construction

Full fleet of 15–20 BWEs operational across multiple segments.

High-volume excavation, extensive spoil management.

Progressive flooding of completed sections for structural testing.

Years 8–9: Finishing & Systems Integration

Final dredging near endpoints.

Slope stabilization, bank reinforcement.

Port facility expansions at Salina Cruz & Coatzacoalcos.

System testing with pilot shipping runs.

Year 10: Inauguration & Operational Launch

Canal officially opens to commercial traffic.

7. COST & LABOR ESTIMATES

7.1 Budget Ballpark

Equipment & Machinery:

15–20 BWEs: $2–3+ billion.

Drilling rigs, dozers, dredges, conveyors: $5–7 billion.

Construction & Earthworks:

Excavation of billions of m³ + causeways: $30–50 billion.

Infrastructure (camps, roads, power, water):

$10–15 billion.

Environmental & Social Mitigation:

$5–10+ billion.

Contingencies & Overruns:

20–30% on top of direct costs.

Likely Total: $60–100+ billion.

7.2 Manpower

Peak Construction: ~50,000–80,000 workers across all segments.

Support Staff: 20,000–30,000 in management, logistics, catering, security, etc.

Specialized Engineers (geotech, BWE specialists, blasting experts): ~5,000–10,000 globally recruited.

8. ENVIRONMENTAL & SOCIAL FACTORS

Ecosystem Disruption

The isthmus has diverse habitats: farmland, wetlands, tropical forest pockets. Large-scale clearing must be mitigated with reforestation, wildlife corridors, and careful water management.

Water Table & Flooding

Creating a sea-level canal can alter local aquifers and drainage patterns. Planning for flood control and silt management is crucial.

Community Relations

Land acquisition, relocation (if any), and benefit-sharing for local communities (jobs, infrastructure improvements).

9. CONCLUSION & RECOMMENDATIONS

Route Feasibility

The specified coordinates offer a relatively direct alignment from 16°11'N, 95°08'W (Pacific) to 18°09'N, 94°24'W (Gulf).

Lowland segments (Start → WP5 and WP6 → End) are prime for heavy BWE use, while the mid-ridge area requires partial drilling/blasting.

Execution Strategy

Parallel Segment Excavation with 15–20 BWEs to meet a sub-10-year schedule.

Major Spoil Utilization for land reclamation near both coasts and building protective embankments.

Key Next Steps

Detailed LIDAR Surveys: Identify micro-topography & pinpoint rock outcrops.

Borehole Drilling: Classify soil/rock layers precisely.

Environmental Approvals: Rapid-track EIA but ensure robust mitigation frameworks.

Industry Partnerships: Confirm BWE supply chain, set up local assembly lines in the U.S. if the plan is to expedite manufacturing.

With a 150+ billion dollar budget and strong political support, this route can be constructed in ~10 years—but it requires massive coordination, robust engineering solutions, and rigorous environmental management to succeed.

Share this post